Epoxy coatings have gained significant popularity for their versatility, durability, and aesthetic appeal. Whether enhancing the floors of a home, a bustling commercial space, or a demanding industrial environment, epoxy coatings provide a resilient solution. This article delves into the myriad applications of epoxy coatings, the impressive benefits they offer, and key maintenance tips to ensure they remain in pristine condition.

Applications of Epoxy Coating

Residential Applications

In residential settings, epoxy coatings are often used to upgrade garages, basements, and patios. Their ability to withstand heavy use while maintaining a sleek appearance makes them ideal for these areas. In garages, epoxy protects the concrete from oil stains, chemical spills, and physical damage, creating a clean and polished look. In basements, epoxy floors help prevent moisture penetration and mold growth, while in patios, they offer a stylish and weather-resistant finish that enhances outdoor living spaces.

Commercial Uses

Epoxy coatings are a favorite in commercial environments such as retail stores, restaurants, and office buildings. The high foot traffic in these spaces demands a flooring solution that is both durable and attractive. Epoxy floors meet these requirements by offering a variety of colors and finishes that can be customized to match the branding and decor of any business. Additionally, their easy-to-clean surface makes them a practical choice for maintaining a pristine and professional environment.

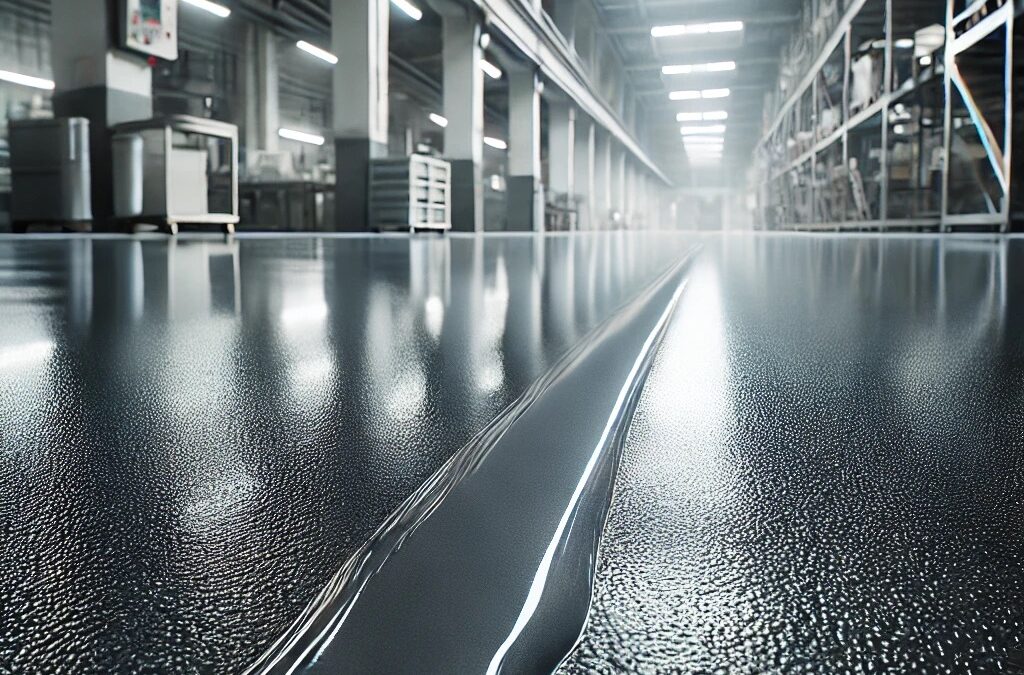

Industrial Settings

In industrial environments, epoxy coatings are indispensable due to their robust nature. Factories, warehouses, and manufacturing plants benefit from epoxy’s resistance to heavy machinery, forklifts, and constant foot traffic. These coatings are also highly resistant to chemicals, oils, and other industrial substances, ensuring that the floors remain undamaged and safe. Furthermore, epoxy floors can be designed with anti-slip additives to enhance safety in areas prone to spills and wet conditions.

Benefits of Epoxy Coatings

Exceptional Durability

Epoxy coatings are renowned for their durability. Once applied, they form a hard, resilient surface that can withstand significant wear and tear. This makes them suitable for high-traffic areas and environments where durability is essential. The longevity of epoxy coatings reduces the need for frequent repairs or replacements, making them a cost-effective flooring solution.

Aesthetic Versatility

One of the standout features of epoxy coatings is their aesthetic versatility. Available in a wide range of colors, patterns, and finishes, epoxy can be customized to achieve various looks, from sleek and modern to bold and vibrant. This flexibility allows homeowners and businesses to create unique, visually appealing spaces that reflect their personal style or brand identity.

Chemical and Stain Resistance

Epoxy coatings offer excellent resistance to a wide range of chemicals and stains. This makes them ideal for environments where spills and chemical exposure are common, such as garages, laboratories, and industrial facilities. The non-porous nature of epoxy prevents spills from penetrating the surface, ensuring that the floor remains unblemished and easy to clean.

Ease of Maintenance

Maintaining epoxy coatings is straightforward, thanks to their seamless and non-porous surface. Regular cleaning with a mild detergent and water is usually sufficient to keep the floors looking pristine. This ease of maintenance is particularly beneficial in commercial and industrial settings, where cleanliness and hygiene are paramount.

Maintenance Tips for Long-Lasting Results

Regular Cleaning

Regular cleaning is essential to maintain the appearance and integrity of epoxy coatings. Sweep or vacuum the floor regularly to remove dust and debris. For deeper cleaning, use a mop with a mild detergent and water. Avoid using abrasive cleaners or tools that could scratch the surface.

Spill Management

Promptly clean up any spills, especially those involving harsh chemicals, to prevent potential staining or damage. Although epoxy is resistant to many substances, it’s best to address spills quickly to maintain the floor’s pristine condition.

Periodic Inspections

Conduct regular inspections to identify any signs of wear or damage. Look for scratches, chips, or areas where the coating may be thinning. Addressing minor issues early can prevent them from becoming more significant problems that could compromise the floor’s durability.

Reapplication of Topcoat

Depending on the level of traffic and use, consider reapplying a topcoat every few years to maintain the protective layer. The topcoat provides an additional barrier against wear and tear, helping to preserve the epoxy’s appearance and functionality.

Key Takeaways

- Versatile Applications: Epoxy coatings are suitable for residential, commercial, and industrial settings, offering a durable and attractive flooring solution for various environments.

- Impressive Benefits: These coatings provide exceptional durability, aesthetic versatility, chemical resistance, and ease of maintenance, making them a superior choice for many applications.

- Simple Maintenance: Regular cleaning, prompt spill management, periodic inspections, and occasional topcoat reapplication will help ensure that epoxy coatings remain in excellent condition for years to come.

Epoxy coatings are a practical and aesthetically pleasing choice for those seeking a resilient and low-maintenance flooring solution. Their versatility and robustness make them an excellent investment for any space.

Frequently Asked Questions (FAQs)

1. What is epoxy coating?

Epoxy coating is a highly durable and protective layer that can be applied to a variety of surfaces, including concrete, metal, and wood. This coating consists of a two-component system made up of epoxy resin and a hardener. When these two components are mixed, they chemically react to form a tough, rigid plastic material that adheres strongly to the substrate. The result is a seamless, hard-wearing finish that enhances the durability, chemical resistance, and aesthetic appeal of the surface. Epoxy coatings are widely used in both residential and commercial applications due to their resilience and versatile nature.

2. Where can epoxy coating be applied?

Epoxy coatings are incredibly versatile and can be applied in numerous settings:

- Residential Garages: In homes, epoxy is often used to upgrade garage floors. It provides a protective barrier against oil stains, chemical spills, and physical damage while creating a clean, polished look.

- Commercial Kitchens: In commercial kitchens, epoxy coatings offer a hygienic, easy-to-clean surface that withstands heavy foot traffic and exposure to food spills and cleaning chemicals.

- Industrial Warehouses: Industrial settings benefit greatly from epoxy coatings due to their ability to withstand heavy machinery, constant foot traffic, and exposure to various chemicals and oils.

- Retail Spaces and Showrooms: Epoxy can also be used in retail environments to create attractive, durable floors that can handle high foot traffic while maintaining a professional appearance.

- Healthcare Facilities: Hospitals and clinics use epoxy coatings for their seamless, easy-to-clean surfaces that help maintain a sterile environment.

3. What are the benefits of epoxy coating?

Epoxy coatings offer numerous benefits that make them a superior choice for various applications:

- High Durability: Epoxy forms a robust surface that can endure significant wear and tear, making it ideal for high-traffic areas and industrial settings. Its strength reduces the need for frequent repairs or replacements.

- Resistance to Stains and Chemicals: Epoxy is highly resistant to a wide range of chemicals, including oils, acids, and solvents. It also resists stains from spills, ensuring the surface remains clean and attractive over time.

- Customizable Designs: Available in a multitude of colors, patterns, and finishes, epoxy coatings can be customized to match any decor or branding. This flexibility allows for creative and unique designs that enhance the visual appeal of any space.

- Ease of Maintenance: The non-porous, seamless nature of epoxy makes it easy to clean and maintain. Spills can be wiped away effortlessly, and regular sweeping or mopping keeps the floor looking pristine. This low maintenance requirement is particularly advantageous in busy environments.

4. How is epoxy coating applied?

Applying epoxy coating is a meticulous process that involves several crucial steps to ensure a durable and flawless finish:

- Surface Preparation: The first step is to thoroughly clean and prepare the surface. This involves removing any dirt, grease, or existing coatings. Any cracks or imperfections should be repaired to create a smooth, even substrate. Mechanical grinding or shot blasting is often used to open up the surface and enhance the adhesion of the epoxy.

- Mixing Epoxy Resin and Hardener: The epoxy resin and hardener are mixed together to initiate the chemical reaction that will form the durable epoxy coating. This mixture must be prepared precisely according to manufacturer specifications to ensure optimal performance.

- Applying the Mixture: The epoxy mixture is then evenly applied to the prepared surface using rollers or squeegees. Multiple layers may be applied to achieve the desired thickness and durability. Each layer must cure properly before applying the next, ensuring a strong bond and a smooth finish.

- Curing: After the final layer is applied, the floor must be allowed to cure completely. This curing process can take several days, during which the floor should not be disturbed. Once fully cured, the floor forms a seamless, hard-wearing surface that is both durable and visually appealing.

5. How should epoxy coating be maintained?

Maintaining epoxy coatings is straightforward and ensures their longevity and appearance:

- Regular Cleaning: Sweep or mop the floor regularly using a mild detergent and water to remove dust and debris. Avoid using abrasive cleaners or tools that could scratch the surface.

- Spill Management: Promptly clean up any spills, especially those involving chemicals, to prevent potential staining or damage. Although epoxy is resistant to many substances, addressing spills quickly is always best.

- Periodic Inspections: Conduct regular inspections to identify any signs of wear or damage. Addressing minor issues early can prevent them from becoming larger problems that could compromise the floor’s integrity.

- Reapplication of Topcoat: Depending on the level of traffic and use, consider reapplying a topcoat every few years to maintain the protective layer. The topcoat provides an additional barrier against wear and tear, helping to preserve the epoxy’s durability and appearance.