Concrete epoxy has become a favored choice for enhancing and protecting concrete surfaces in various environments. Its combination of durability, aesthetics, and versatility makes it an ideal solution for residential, commercial, and industrial spaces. This article delves into the benefits, applications, and installation tips for concrete epoxy, providing a comprehensive understanding of why it stands out as a superior flooring option.

Benefits of Concrete Epoxy

Concrete epoxy offers a multitude of benefits that make it an exceptional choice for flooring:

Durability and Longevity

One of the most significant advantages of concrete epoxy is its unparalleled durability. The epoxy coating forms a tough, protective layer that can withstand heavy foot traffic, machinery, and even vehicular loads. This resilience ensures that the floor remains intact and functional for many years, reducing the need for frequent repairs or replacements.

Aesthetic Appeal

Concrete epoxy is not only functional but also visually appealing. It comes in a variety of colors, finishes, and patterns, allowing for customization to match any decor. Whether you prefer a sleek, modern look or a more intricate design, concrete epoxy can transform a mundane concrete surface into a stunning focal point.

Chemical Resistance

Epoxy coatings are highly resistant to a wide range of chemicals, including oils, solvents, and acids. This resistance makes them ideal for environments where spills and chemical exposure are common, such as garages, laboratories, and industrial facilities.

Easy Maintenance

The non-porous and seamless nature of concrete epoxy makes it incredibly easy to clean and maintain. Spills can be wiped away with minimal effort, and regular sweeping or mopping keeps the floor looking pristine. This low maintenance requirement is a significant advantage for busy spaces.

Enhanced Safety

Concrete epoxy can be customized with anti-slip additives, enhancing safety in areas prone to wet conditions. This feature is particularly beneficial in commercial kitchens, hospitals, and industrial facilities where slip hazards must be minimized.

Applications of Concrete Epoxy

Concrete epoxy is versatile and can be applied in various settings, each benefiting from its unique properties:

Residential Spaces

In homes, concrete epoxy is often used in garages, basements, and patios. Its durability ensures that it can withstand heavy use, while its aesthetic options allow homeowners to create stylish, functional spaces. In the garage, epoxy can protect the concrete from oil stains and damage, while in basements, it can prevent moisture penetration and mold growth.

Commercial Environments

Epoxy flooring is a popular choice for commercial spaces such as retail stores, showrooms, and restaurants. Its ability to withstand high foot traffic and its customizable aesthetics make it perfect for creating inviting and professional environments. Additionally, its easy maintenance ensures that these busy spaces remain clean and attractive with minimal effort.

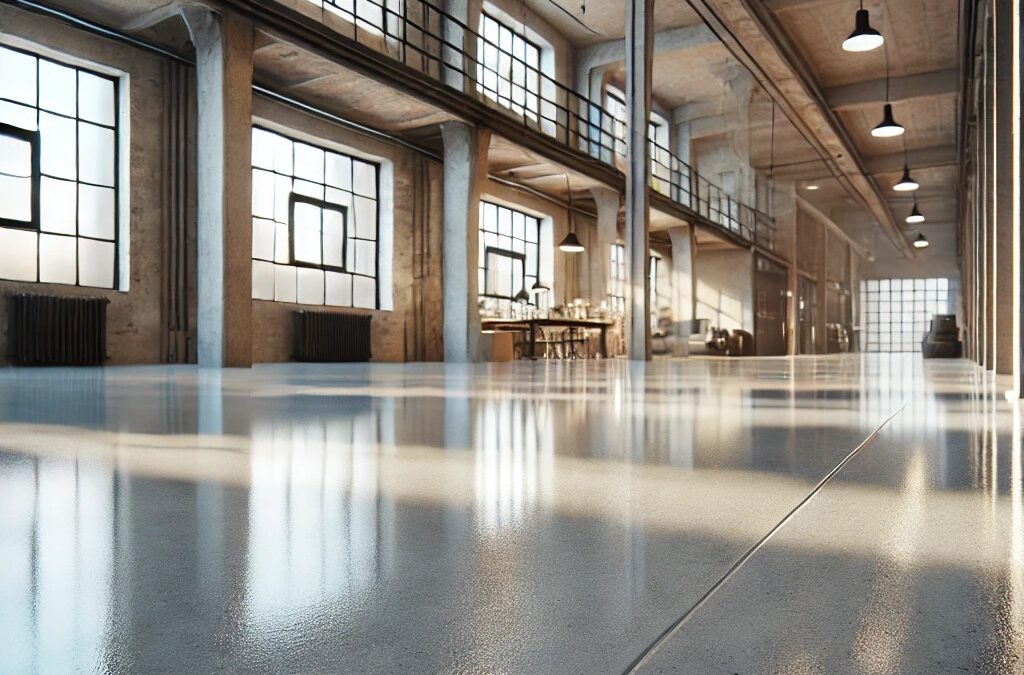

Industrial Settings

In industrial environments, epoxy coatings provide a durable and chemical-resistant surface that can handle the rigors of heavy machinery, forklifts, and constant foot traffic. Factories, warehouses, and manufacturing plants benefit from epoxy flooring’s robustness, safety features, and resistance to wear and tear.

Installation Tips for Optimal Results

Installing concrete epoxy requires precision and attention to detail to ensure a flawless and long-lasting finish. Here are some essential tips for achieving optimal results:

Surface Preparation

Proper surface preparation is crucial for a successful epoxy installation. The concrete substrate must be thoroughly cleaned to remove dirt, grease, and any existing coatings. Any cracks or imperfections in the concrete should be repaired to create a smooth and even surface. Mechanical grinding or shot blasting is often used to open up the concrete’s pores, enhancing the adhesion of the epoxy.

Primer Application

Once the surface is prepped, a primer is applied to promote strong adhesion between the concrete and the epoxy. The primer penetrates the concrete, creating a stable base for the subsequent epoxy layers.

Epoxy Application

The epoxy resin and hardener mixture is then applied to the primed surface. This process often involves multiple layers to achieve the desired thickness and durability. Each layer must cure properly before applying the next, ensuring a strong bond and a smooth finish.

Decorative Elements

If decorative finishes such as flakes or metallic pigments are desired, they are added during the application process. These elements can create unique designs and enhance the floor’s visual appeal.

Topcoat Application

A topcoat is applied to seal the floor and provide additional protection against wear, chemicals, and UV rays. The topcoat also enhances the floor’s gloss and overall appearance, giving it a polished finish.

Key Takeaways

- Exceptional Durability: Concrete epoxy offers superior strength and longevity, making it suitable for a variety of environments.

- Aesthetic Flexibility: Available in numerous colors and finishes, epoxy can be customized to enhance any space.

- Chemical Resistance: Ideal for settings exposed to chemicals, epoxy flooring withstands spills without damage.

- Low Maintenance: Easy to clean and maintain, epoxy floors remain pristine with minimal effort.

- Enhanced Safety: Anti-slip options improve safety, making epoxy suitable for both residential and commercial applications.

Concrete epoxy is a versatile and practical choice for those seeking a durable, attractive, and low-maintenance flooring solution. Whether in a home, business, or industrial facility, epoxy floors provide long-lasting benefits that meet a wide range of needs.

Frequently Asked Questions (FAQs)

1. What is concrete epoxy?

Concrete epoxy is a highly durable coating applied to concrete surfaces, designed to enhance the durability, chemical resistance, and aesthetic appeal of the floor. This coating consists of a two-part system made up of epoxy resin and a hardener. When mixed together, these components chemically react to form a rigid plastic material that bonds exceptionally well to concrete surfaces. The result is a seamless, hard-wearing finish that protects the concrete and transforms its appearance, making it suitable for a wide range of applications in residential, commercial, and industrial settings.

2. What are the benefits of using epoxy on concrete floors?

Using epoxy on concrete floors offers a host of benefits, making it a popular choice for various environments:

- Increased Durability: Epoxy coatings create a robust surface that can withstand heavy foot traffic, machinery, and even vehicular loads. This makes it ideal for high-traffic areas and industrial settings where durability is paramount.

- Resistance to Stains and Chemicals: Epoxy floors are highly resistant to a wide range of chemicals, including oils, solvents, and acids. This resistance protects the floor from damage and stains, ensuring it remains in excellent condition over time.

- Improved Aesthetics: Available in a variety of colors, finishes, and patterns, epoxy coatings can significantly enhance the visual appeal of concrete floors. Whether you prefer a sleek, modern look or a more intricate design, epoxy allows for extensive customization to suit any decor or branding.

- Ease of Maintenance: The non-porous and seamless nature of epoxy flooring makes it incredibly easy to clean and maintain. Spills can be wiped away with minimal effort, and regular sweeping or mopping keeps the floor looking pristine. This low maintenance requirement is a significant advantage for busy spaces.

3. Where can concrete epoxy be used?

Concrete epoxy is incredibly versatile and can be used in a wide range of settings:

- Residential Garages: In homes, epoxy flooring is often used in garages to protect the concrete from oil stains, chemical spills, and damage from heavy vehicles. It also enhances the garage’s overall appearance, creating a clean and polished look.

- Commercial Spaces: Epoxy flooring is a popular choice for commercial environments such as retail stores, showrooms, and restaurants. Its durability allows it to handle high foot traffic, while its customizable aesthetics create inviting and professional spaces.

- Industrial Facilities: Factories, warehouses, and manufacturing plants benefit from the durability and chemical resistance of epoxy flooring. It can withstand the rigors of heavy machinery, forklifts, and constant foot traffic, making it a reliable flooring solution for industrial settings.

- Healthcare Environments: Hospitals and clinics require hygienic, easy-to-clean surfaces. Epoxy flooring provides a seamless finish that resists bacteria and pathogens, ensuring a sterile environment.

4. How is concrete epoxy applied to floors?

The application of concrete epoxy is a meticulous process that ensures a durable and flawless finish:

- Surface Preparation: Proper surface preparation is crucial for a successful epoxy installation. The concrete substrate must be thoroughly cleaned to remove dirt, grease, and any existing coatings. Any cracks or imperfections in the concrete should be repaired to create a smooth and even surface. Mechanical grinding or shot blasting is often used to open up the concrete’s pores, enhancing the adhesion of the epoxy.

- Mixing Epoxy Resin and Hardener: The epoxy resin and hardener are mixed together to initiate the chemical reaction that will form the durable epoxy coating. This mixture must be prepared precisely according to manufacturer specifications to ensure optimal performance.

- Applying the Mixture: The epoxy mixture is then evenly applied to the prepared surface using rollers or squeegees. Multiple layers may be applied to achieve the desired thickness and durability. Each layer must cure properly before applying the next, ensuring a strong bond and a smooth finish.

- Curing: After the final layer is applied, the floor must be allowed to cure completely. This curing process can take several days, during which the floor should not be disturbed. Once fully cured, the floor forms a seamless, hard-wearing surface that is both durable and visually stunning.

5. How should concrete epoxy be maintained to prolong its lifespan?

Maintaining concrete epoxy flooring is straightforward and ensures its longevity and appearance:

- Regular Cleaning: Sweep or mop the floor regularly using a mild detergent and water to remove dust and debris. Avoid using harsh chemicals or abrasive cleaning tools that could damage the surface.

- Spill Management: Promptly clean up any spills, especially those involving chemicals, to prevent potential staining or damage. Although epoxy is resistant to many substances, addressing spills quickly is always best.

- Periodic Inspections: Conduct regular inspections to identify any signs of wear or damage. Addressing minor issues early can prevent them from becoming larger problems that could compromise the floor’s integrity.

- Reapplication of Topcoat: Depending on the level of traffic and wear, consider reapplying a topcoat every few years to maintain the protective layer and keep the floor looking fresh. The topcoat provides an additional barrier against wear and tear, helping to preserve the epoxy’s durability and appearance.