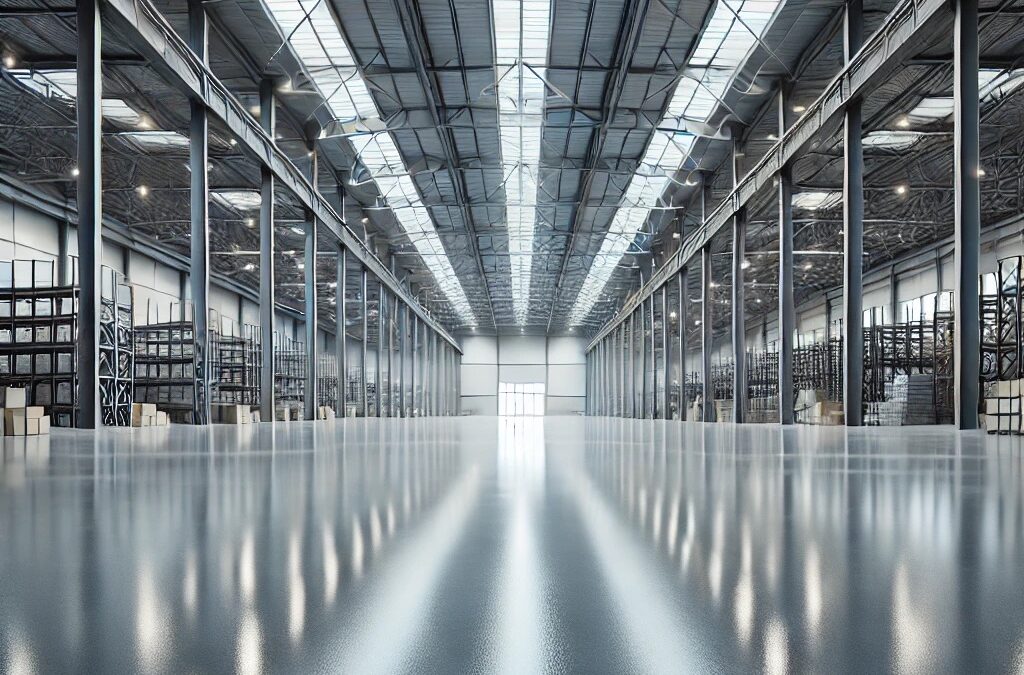

Industrial environments demand flooring solutions that withstand heavy use, harsh chemicals, and constant foot traffic. Enter industrial epoxy flooring—a marvel of modern engineering designed to meet these rigorous requirements. With its robust durability and exceptional performance, epoxy flooring has become the go-to choice for commercial and industrial spaces. Let’s delve into the myriad benefits of this resilient flooring solution.

Unparalleled Durability

Industrial epoxy flooring is synonymous with strength and longevity. Comprising a combination of resin and hardener, this flooring system forms a rigid plastic material that bonds exceptionally well to concrete surfaces. This results in a durable and highly resilient surface that can withstand heavy machinery, substantial loads, and the wear and tear of daily operations.

One of the most remarkable attributes of epoxy flooring is its resistance to abrasion. Unlike traditional flooring materials that may chip, crack, or wear down over time, epoxy maintains its integrity even under the most demanding conditions. Its robust nature ensures that industrial spaces remain safe and functional, reducing the need for frequent repairs or replacements.

Superior Performance Benefits

Beyond durability, industrial epoxy flooring offers a host of performance benefits that make it an ideal choice for various settings. Its seamless and non-porous surface creates a hygienic environment by preventing the accumulation of dirt, bacteria, and other contaminants. This is particularly advantageous for industries where cleanliness is paramount, such as food processing plants, pharmaceutical facilities, and laboratories.

Epoxy flooring is also renowned for its chemical resistance. It can withstand exposure to a wide range of harsh chemicals, including solvents, acids, and alkalis, without deteriorating. This resistance ensures that the flooring remains intact and performs optimally, even in environments where spills and chemical exposure are common.

Additionally, epoxy flooring enhances the aesthetic appeal of industrial spaces. Available in an array of colors and finishes, it allows businesses to customize their floors to reflect their branding or create designated zones within a facility. The glossy finish of epoxy floors not only improves visibility but also contributes to a polished and professional look.

Installation Process

The installation of industrial epoxy flooring involves several meticulous steps to ensure a flawless and durable finish. The process begins with thorough surface preparation, where the existing concrete is cleaned, repaired, and sometimes ground to create a suitable substrate. This step is crucial, as any imperfections or contaminants can affect the adhesion and longevity of the epoxy coating.

Once the surface is prepped, a primer layer is applied to promote adhesion between the concrete and the epoxy. This is followed by the application of the epoxy resin, which is typically done in multiple layers to achieve the desired thickness and durability. Each layer needs to cure properly before the next is applied, ensuring a strong bond and a smooth finish.

The final step involves applying a topcoat, which provides additional protection against abrasion, chemicals, and UV exposure. The topcoat also enhances the aesthetic appeal by adding a glossy sheen or a matte finish, depending on the desired look. The entire installation process requires precision and expertise to ensure optimal performance and longevity.

Maintenance Tips

Maintaining industrial epoxy flooring is relatively straightforward, making it an attractive option for busy industrial settings. Regular cleaning with a soft broom or mop can prevent the buildup of dust and debris, while periodic deep cleaning with a mild detergent can keep the surface looking pristine.

To preserve the integrity of the epoxy coating, it is essential to address spills and stains promptly. While epoxy is highly resistant to chemicals, prolonged exposure can cause discoloration or damage. Using appropriate cleaning agents and avoiding abrasive tools will help maintain the floor’s appearance and performance.

Additionally, it is advisable to conduct periodic inspections to identify any signs of wear or damage. Addressing minor issues early can prevent them from escalating into more significant problems, ensuring the longevity of the flooring system. By following these maintenance tips, businesses can enjoy the benefits of industrial epoxy flooring for many years.

Key Takeaways

- Exceptional Durability: Industrial epoxy flooring offers unparalleled strength, capable of withstanding heavy machinery, substantial loads, and daily wear and tear without chipping or cracking.

- Superior Performance: The seamless and non-porous surface creates a hygienic environment, resists a wide range of harsh chemicals, and enhances the aesthetic appeal of industrial spaces.

- Customizable Aesthetics: Available in various colors and finishes, epoxy flooring can be tailored to reflect branding or create designated zones within a facility.

- Precision Installation: The meticulous installation process, including thorough surface preparation and multiple layers of epoxy, ensures a flawless and durable finish.

- Easy Maintenance: Regular cleaning and prompt attention to spills and stains, along with periodic inspections, help maintain the floor’s appearance and performance over time.

- Long-Term Investment: Investing in industrial epoxy flooring enhances the safety, functionality, and professional look of industrial spaces, ensuring a productive environment for years to come.

Frequently Asked Questions (FAQs)

1. What is industrial epoxy flooring?

Industrial epoxy flooring is a robust and highly resilient coating applied to concrete floors primarily in commercial and industrial settings. This flooring system consists of a mixture of epoxy resin and hardener, which chemically reacts to form a rigid plastic material. The result is a seamless, durable surface that enhances the floor’s strength, chemical resistance, and overall aesthetics. It is specifically designed to withstand the rigors of heavy machinery, substantial loads, and constant foot traffic, making it an ideal choice for demanding environments.

2. What are the benefits of industrial epoxy flooring?

Industrial epoxy flooring offers numerous benefits, making it a popular choice for various industries:

- High Durability: It provides exceptional strength, able to withstand heavy machinery and substantial loads without chipping or cracking.

- Chemical Resistance: Epoxy flooring is resistant to a wide range of chemicals, including acids, alkalis, and solvents, ensuring longevity even in harsh environments.

- Ease of Maintenance: Its seamless and non-porous surface makes cleaning and maintenance straightforward, preventing the buildup of dirt and bacteria.

- Enhanced Safety: Anti-slip options are available to improve safety in work environments, reducing the risk of accidents.

- Improved Aesthetics: Available in various colors and finishes, epoxy flooring can be customized to match the branding or specific design requirements of the facility, providing a polished and professional appearance.

3. How is industrial epoxy flooring installed?

The installation of industrial epoxy flooring involves several detailed steps to ensure a durable and seamless finish:

- Surface Preparation: The existing concrete surface is thoroughly cleaned, repaired, and sometimes ground to create a suitable substrate free of contaminants and imperfections.

- Application of Primer: A primer layer is applied to promote strong adhesion between the concrete and the epoxy.

- Epoxy Resin Application: The epoxy resin and hardener mixture is applied in multiple layers, each allowed to cure properly before the next is added. This builds up the desired thickness and ensures a robust finish.

- Curing Process: The epoxy needs to cure completely to form a strong bond and achieve maximum durability.

- Topcoat Application: A topcoat is applied to provide additional protection against abrasion, chemicals, and UV exposure, enhancing the floor’s durability and appearance.

4. What industries benefit from industrial epoxy flooring?

Industrial epoxy flooring is beneficial to a wide range of industries due to its durability and performance:

- Manufacturing Facilities: Withstand the wear and tear of heavy machinery and constant foot traffic.

- Warehouses: Durable surface that can handle heavy loads and forklifts.

- Pharmaceutical Plants: Creates a hygienic and easy-to-clean environment essential for maintaining cleanliness standards.

- Food Processing Facilities: Resistant to chemicals and easy to maintain, ensuring a sanitary environment.

- Automotive Workshops: Resists oils, greases, and other chemicals, providing a safe and clean working area.

- Healthcare Facilities: Seamless surface prevents the buildup of bacteria and other contaminants, crucial for sterile environments.

5. How should industrial epoxy flooring be maintained?

Maintaining industrial epoxy flooring is straightforward, ensuring its longevity and appearance:

- Regular Cleaning: Use a mild detergent and water to clean the floor regularly, preventing dirt and debris buildup.

- Routine Inspections: Periodically inspect the floor for any signs of damage or wear and address minor issues promptly to prevent them from becoming major problems.

- Periodic Reapplication: Apply topcoats or sealants periodically to maintain the protective layer and enhance the floor’s durability and appearance.

- Spill Management: Promptly clean any chemical spills to prevent potential staining or damage, despite the floor’s high resistance to chemicals.